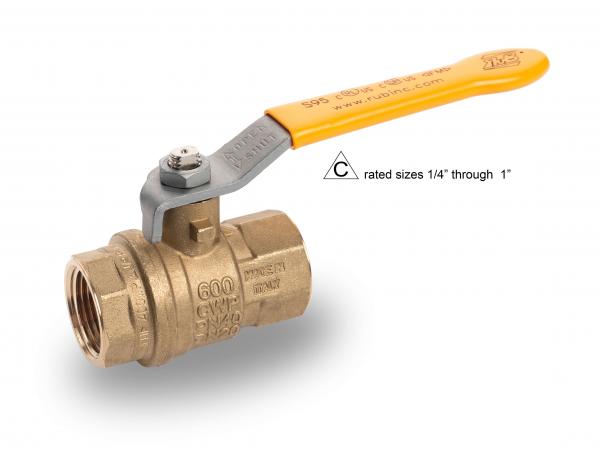

ボールバルブ

s.7350 3 方向 4面シート T-ポート

フルボア

鍛造真鍮性ボールバルブ

1/2B〜1B(15A〜25A)

s.7350 3 方向 4面シート T-ポート

ねじ規格

管用テーパねじ R, Rc [ISO 7/1]

圧力

20 bar / 300 PSI

サイズ

1/2"

3/4"

1"

1.1/4"

1.1/2"

2"

接続

メネジ構造

材質

ニッケルメッキ真鍮性

ボア種類

フルボア

特別な構成

T-ポート三方バルブ

Temperature min

-20 °C / -4 °F

Temperature max

+150 °C / 302 °F