マルチポートバルブであるs.7350シリーズは、省コスト化、および省スペース化を図ります。本製品は、4面シートの採用により全て のポートにボールシートを採用しているため、適用範囲が大きく拡大。どのポートも、遮断可能。ボールポート構成の特定化、およ び独自のTポート設計によって、流れ方向を自由に選ぶことができます。従来は必要だった複数の流体搬送ラインの合理化・簡素化を実現し、設備全体のコスト削減にも、大きく貢献する万能バルブです。

技術データ

- 100%シールテストを保証

- 金属間可動部なし

- メンテナンスフリー

- シリコンフリー潤滑剤使用

- クロームメッキされた真鍮ボールの高い耐久性

- どのボール方向でも、好パフォーマンスを発揮

- 剛健な作り

- 熱鍛造サンドブラスト処理を施した、外部ニッケルメッキボディ

及びエンドキャップ - ISO 5211、および DIN 3337 に準ずるマウントフランジを採用

し、アクチュエータ接続向けのユニバーサルジョイントに対応 - EN12165及びEN12164に準拠する高品質の真鍮材を使用

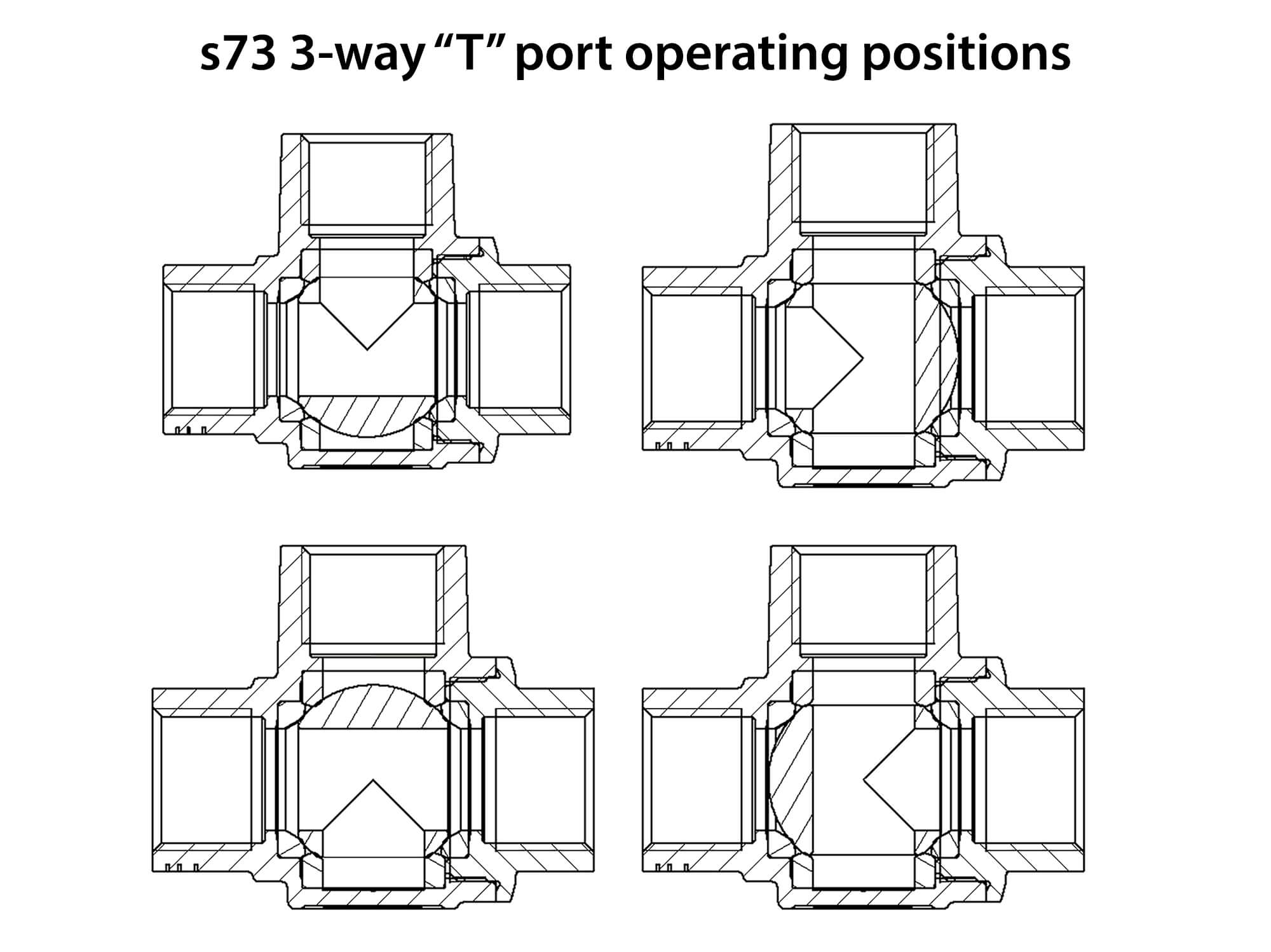

- 3-方向 T ポート 設計で、複数流路に対応

- 飛び出し防止設計ステムで安全確保

- 二枚のFPM製Oリングがステムの安全性を確保

- フレキシブルリップ設計の純PTFEシート

- 4ヵ所設計で、さまざまな流体に対応

- ISO 7/1、BS21 BSPT テーパーネジ仕様(JIS B 0203 相当)

- フルボア最大流量を確保

- ラック及びピニオン式 ニューマチッククアクチュエータ

(スプリングリターン式またはダブルアクティング式) - アクセサリーとして、またはすでに取り付けられているロッ

ク可能なハンドル - スクリュー付きアダプターフランジキット

- EN 10226-1、ISO 228 平行メス x メスネジ

- ANSI B.1.20.1 NPTメネジ構造

- カスタム設計

- ステンレス製ステム

- 2 シート L-ポート設計 (s.7650)

- 耐圧:2MPa (300 PSI)[常温・通常圧]

- 温度:-20℃ ~ +150℃

注意: 流体の凍結はバルブ本体の損傷に繋がる恐れがあります

- RoHS 準拠品

注意: 認証は特定の設計・サイズに適応されます

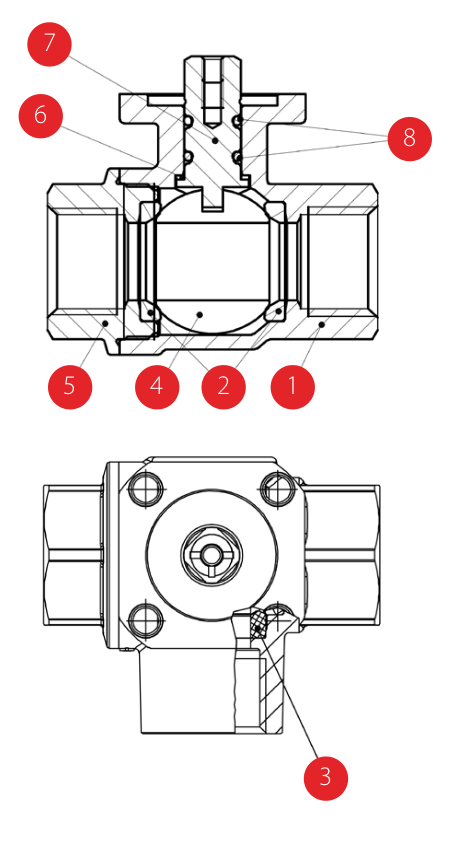

| 部品説明 | 個数 | 材質 |

|---|---|---|

|

ニッケルメッキボディ (外部ニッケルメッキ・内部ニッケル メッキ無し)

|

1

|

CW617N (C3771相当)

|

|

シート

|

2

|

PTFE

|

|

シート

|

2

|

PTFE

|

|

クロームメッキボール

|

1

|

CW617N (C3771相当)

|

|

ニッケルメッキエンドキャップ (外部ニッケルメッキ・内部ニッケル メッキ無し)

|

1

|

CW617N (C3771相当)

|

|

ワッシャー

|

1

|

PTFEカーボン充填25%

|

|

ニッケルメッキステムOリング設計

|

1

|

CW617N (C3771相当)

|

|

Oリング

|

2

|

FPM

|